Everyone has probably been there. You have something you need to fix on your car’s engine. You buy a specific tool that allows you to correct whatever is wrong. Because it’s specialized, the tool is expensive, and when you’re done it is put on the shelf in your shed and is not touched again for quite a long time.

Expensive tools just sitting on shelf

Two months later, you need to fix something else on an engine, but this time on your truck. The problem is very similar to the repair on the car. The two vehicles are different enough that the expensive tool sitting on the shelf in your shed won’t help to repair the truck so you are forced to buy another tool. This new tool looks similar to the other one but is different enough that you now have two expensive tools sitting on your shelf.

First ratcheting socket wrench, made by J.J. Richardson, 1863.

There are tools in the shed that are specialized but still have a way to interchange an attachment so that you can fix both the car and the truck. For example, a ratchet set is interchangeable. The ratchet can loosen a bolt on the car engine and then be reconfigured with a different socket to also loosen a bolt on the truck engine. This means the ratchet set is used over and over and feels like a worthwhile investment.

In the world of Automated Test Equipment (ATE), most often the ATE is the very specialized tool with a single purpose, setup to test one device only, and often sits there taking up space more often than it is used. A purpose-built I/O provides a direct line to interfacing with the equipment, but this approach complicates the design if multiple items are going to be supported by the ATE, and despite this complexity, still ultimately limits future flexibility.

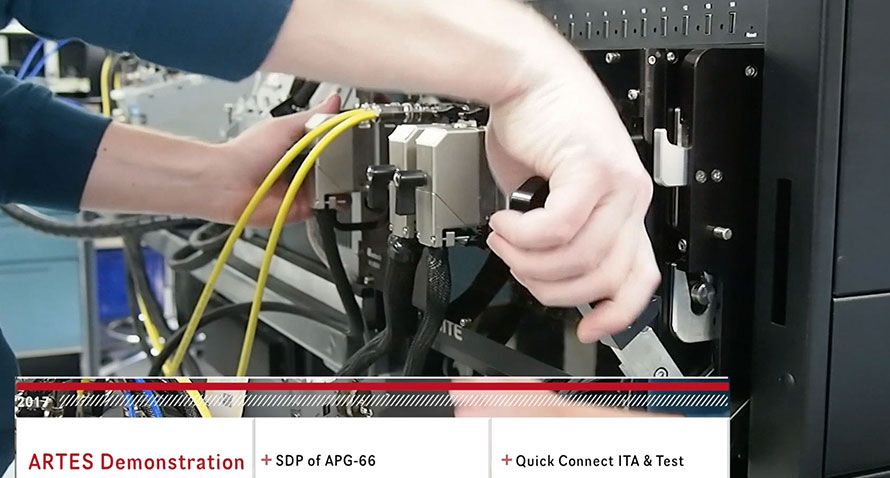

Watch video of how reconfigurable I/O allows multiple tests with a single test stand http://bit.ly/reconfigIO

ATEs can require a large footprint on a repair shop floor. Another issue is that the electronic device the ATE is specifically designed to test does not come into the shop often enough to warrant its expense. However, when the item does arrive and is in need of evaluation, the automated test equipment is invaluable.

Reconfigurable Input/Output I/O allows multiple tests with a single test stand

Having a reconfigurable input/output to the automated test equipment is the socket to the ratchet set. When you can have an interface that allows connections to many different electronics then you can use the one tool over and over again. As an item comes into the repair depot and needs diagnosing, you simply switch out the interchangeable section, the “socket”, so that you can begin performing the work with the ATE, the “ratchet”.

Reconfigurable Input/Output (I/O) means the connection from a test station to a Unit Under Test (UUT) can be reconfigured from one device to another. By building in hardware that allows a test engineer to disconnect one interface and then reconnect another, the ATE becomes a tool more like the ratchet set instead of a specialized tool good for only one device.

An Interface Test Adapter (ITA) like that of the ARTES automated test stand allows for specific connectors and I/O interfacing for each type of equipment being tested. Use of an ITA eliminates the need to limit the design, which would prevent future expansion of test capability. Analog, digital, power, and RF capabilities can all be exposed or converted as necessary in the ITA. Utilization of commodity and custom PXI/PXIe blocks allows for the ultimate in cost-effective functionality and capability expansion. In the end, the custom layer is just the ITA, and the backing is PXIe or other industry standard devices.

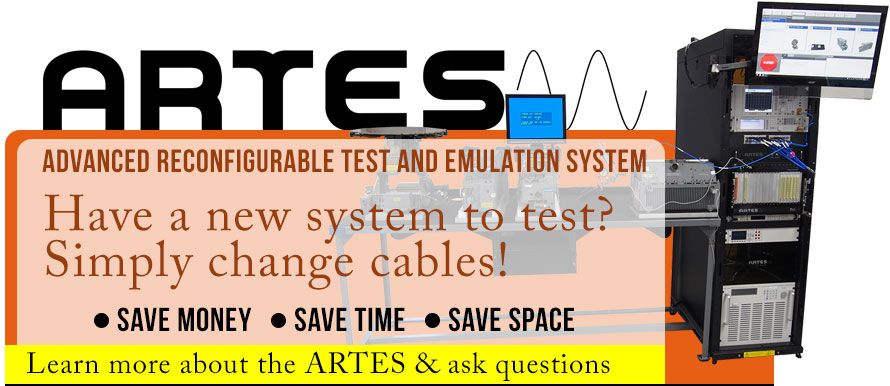

ARTES reconfigurable I/O (RIO) automated test equipment

The ARTES, Advanced Reconfigurable Test and Emulation System is a compact ATE system that can be configured to test a wide variety of devices. It contains reconfigurable I/O for digital, analog, switch matrix, and RF. It can be consolidated into as little as 7U of rack space. If you need to switch tests, you simply grab the ITA and cables designed for that device and connect. Need a new test? Based on requirements, Duotech will produce the new test setup and develop the ITA you need to couple the ARTES to each device, all with little or no additional equipment additions.

Electronic test equipment capabilities…

The ARTES has testing capabilities for a wide variety of electronic systems. Some examples of the electronic test equipment capabilities include the F-16’s APG-66 and APG-68 radar and the F-5’s APQ-159 radar. Many more systems include the APX-113 Combined Interrogator/Transponder, ARC-164, APN-232 CARA, APN-209 and also the DFLCC and FLCC.

The ARTES reconfigurable I/O automated test equipment becomes the multi-use tool in your toolbox for a wide variety of electronic and electromechanical systems. If you would like to learn more about the ARTES, we will be glad to answer your questions. Call or email us today to get answers.