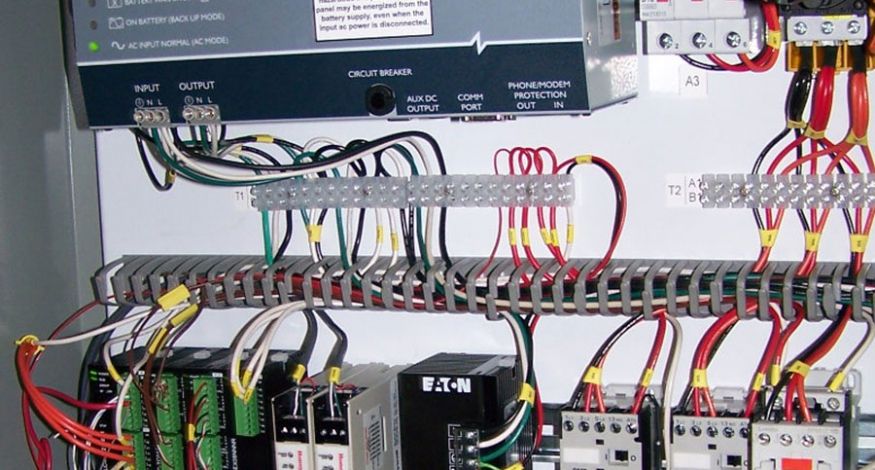

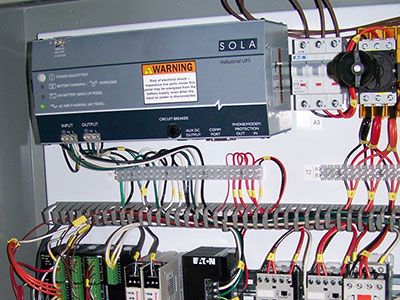

Automated testing, especially in a production environment, requires expertise across many disciplines including automation and controls, instrumentation, data collection and reporting, mechanical fixturing, and software. All of these areas then need to be integrated together while keeping a balance between efficiency (cost, time, operator effort, space usage, etc), safety, and maintainability.

Finding suppliers for highly integrated test systems can be difficult. Control systems vendors have PLCs, interface modules, and more; another vendor provides motors; yet another vendor has motor drives and still others with various sensors. Machine shops can produce precise mechanical components, but only if detailed prints are given to them first, and there are still the issues of integrating buttons, indicators, safeguards, lockouts, interlocks, and proper NEMA sealing. Once the fixture is built, the data it measures needs to be collected and integrated into the proper company computer systems, which brings software development and IT expertise into the requirements mix.

Finding suppliers for highly integrated test systems can be difficult. Control systems vendors have PLCs, interface modules, and more; another vendor provides motors; yet another vendor has motor drives and still others with various sensors. Machine shops can produce precise mechanical components, but only if detailed prints are given to them first, and there are still the issues of integrating buttons, indicators, safeguards, lockouts, interlocks, and proper NEMA sealing. Once the fixture is built, the data it measures needs to be collected and integrated into the proper company computer systems, which brings software development and IT expertise into the requirements mix.

Try to pull together all these items and do it with sufficient documentation so that the system can be used, maintained, repaired, and calibrated in the following years, and it is clear why good automated testing is such a daunting task for many small or medium-sized production companies. Duotech Services excels at providing total solutions for automated testing. Our engineers have experience in studying the application, deriving requirements, and figuring out a testing approach; then designing, building, testing, and integrating an appropriate system. Broad experiential backgrounds using parts from many different automation vendors as well as custom design skills honed in the demanding aerospace industry provides our engineers with the skills needed to arrive at a functional, cost-effective test solution for almost any product or process.

One thing that sets Duotech apart is that we don’t approach the problem by trying to leverage a solution that we already have, because we don’t have a product line. We strive to meet the customer’s requirements with the best possible solution. Nothing shows true customer satisfaction like coming back for another solution, and Duotech has many repeat customers. In fact, in a recent design review meeting, one of the customer operators commented:

One thing that sets Duotech apart is that we don’t approach the problem by trying to leverage a solution that we already have, because we don’t have a product line. We strive to meet the customer’s requirements with the best possible solution. Nothing shows true customer satisfaction like coming back for another solution, and Duotech has many repeat customers. In fact, in a recent design review meeting, one of the customer operators commented:

“If it works as well as the last one they did for us, it’s going to be fantastic!”

What does it take to get someone that excited about product testing? In this case, the operator had been using an old, clumsy test solution prior to the system installed by Duotech, and he had experienced first-hand the improved data accuracy and increased test speed delivered by the system that also reduced his own workload.

Over the next few days, I will overview a few of the especially problematic areas of automated testing and some of the tradeoffs and solutions that Duotech Services uses to produce automation and test solutions that inspire.

Follow up articles to include topics on:

- Mechanical design and construction

- Automation controls

- Sensors and instrumentation

- Data collection and analysis

- Machine vision