If you are going to deploy a new cockpit instrument such as a digital g-meter for use in military aircraft, you need to consider more than just how this product operates independently or as an improvement over other cockpit instruments like it already on the market. You also need to ensure the device will remain operational in many different environmental conditions, that it won’t be affected by other electronic equipment in its area of operation, and that during its operation it is not affecting other electronic equipment nearby.

On the other hand, if you are the responsible party that is considering upgrading your current analog instruments with digital indicators, you need to have confidence that the new electronics have been tested to withstand the planned operational conditions. If the tests applied to the instrument are left up to the developing engineer to establish without any established standards, how would you know the test outcomes are accurate? How would you know the evaluations were strenuous enough that you would have confidence the electronics will operate within correct tolerances, in the toughest of conditions, when the results of failure can cost lives and millions of dollars in equipment?

Standards are required that specify test conditions during development of the electronics to withstand environmental conditions. U.S. Defense Standards, also known as military standards (often designated with MIL-STD when referenced), formally define a series of tests and procedures for performing these tests to determine if an item is capable of meeting necessary requirements. Established by the U.S. Department of Defense, these MIL-STD documents serve to standardize engineering and technical testing requirements for new, existing, or modified products to meet their unique specifications.

Recognizing that a digital g-meter needs to operate in a military aircraft, the engineer should test the product for operation in a low pressure environment like is experienced at altitude in an aircraft. MIL-STD -810F covers environmental exposure to ensure equipment will operate properly in varying temperatures, humidity, altitude, transportation, immersion, and even fungal growth. One of the Laboratory Test Methods in MIL-STD-810F that addresses this is Method 500.4, Low Pressure Altitude, which will test to determine if the G-meter can withstand and operate in a low pressure environment as well as rapid pressure change. This section of 810F provides specific details about decompression rates, limitations, testing duration, what the testing facility should be, and how to execute the test.

There are many other standards referenced when testing electronic equipment during development. A few common military standards are as follows:

- MIL-STD-461 > This standard ensures that your equipment is not susceptible to electromagnetic interference, or is emitting interference characteristics that negatively affect other electronic equipment and subsystem operations.

- MIL-STD-464 > This standard ensures that your equipment is not radiating and affecting other equipment

- MIL-STD-704 > This handbook provides guidance and test methods to ensure your equipment will operate when it is powered in its intended environment.

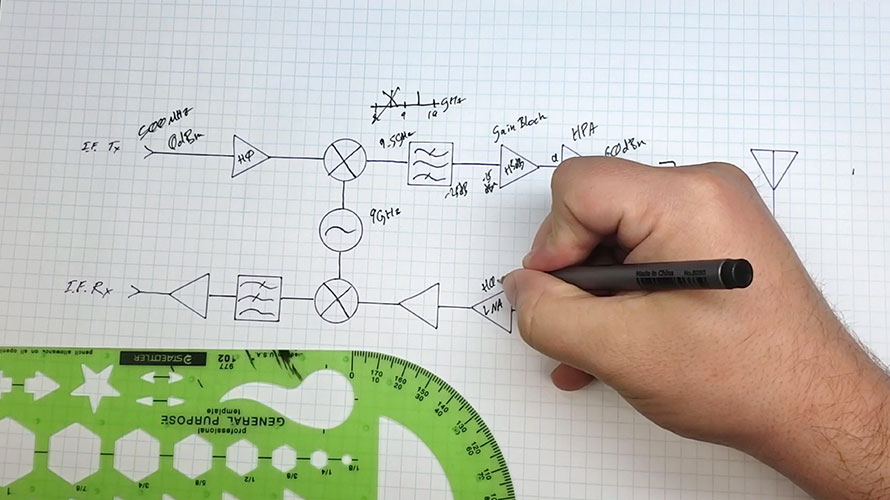

Testing to military standards always requires adapting these tests to your specific application. Duotech Services has experience in planning and executing qualification tests and can help you to make your product testing a success. From planning a testing approach or building Automated Test Equipment to writing test plans and even helping to execute qualification testing, we can work with you to help navigate the intricacies of proper product qualification.