For every engineer, a time arrives when they are tasked with developing an idea into a working model. No technical professional works without having this experience, but the included requirements tend to come with a schedule that seems ambitious at best. What does the electronics designer do when there is no time to design and fabricate an original design? The answer usually rests with selecting a starting point that will allow for a realistic end date. Vendors are increasingly willing to provide power development and evaluation kits to shorten development cycles and reduce design risk. Monetary reward motivates availability of evaluation and prototyping resources.

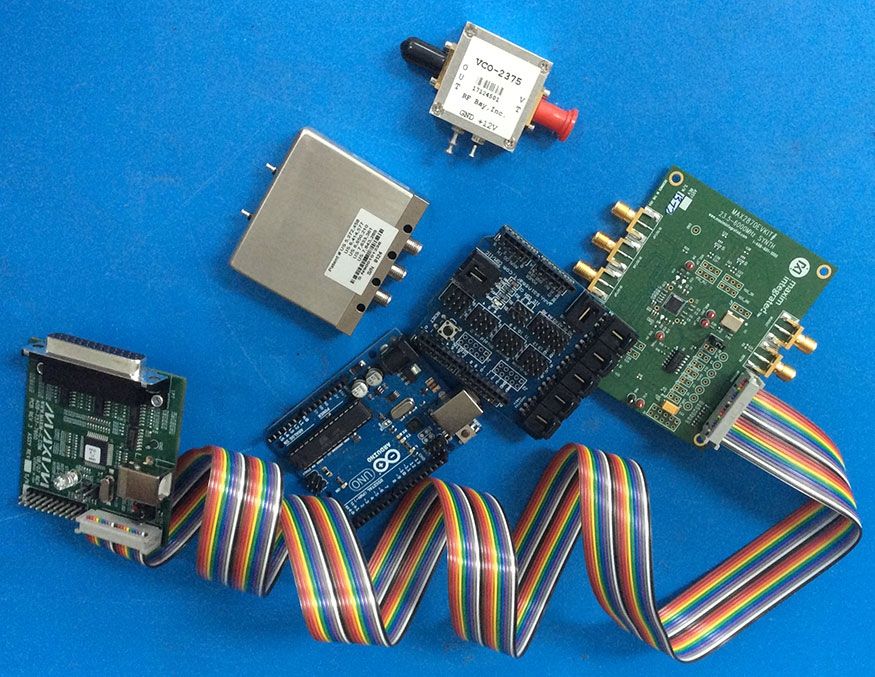

First, consider what design goals and steps are required. A temptation exists to connect development kits and modules without the planning required in an original, organic design. Resist this temptation! A rapidly develop project should not be a poorly planned one.

Many methodologies exist, but consider the following:

- Define the idea

- Requirements

- Gathering

- Development

- Review (be willing to be critical)

- Action plan

- Preliminary design

- Detailed design

- Model, diagrams, schematics

- Build and package

- Evaluation

- Schedule

- Requirements

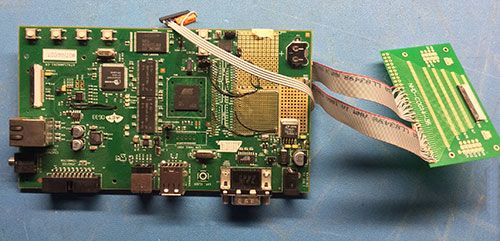

In a world where PCBs can be turned overnight, does enough value exist in manufacturing them in-house? For Duotech and companies even larger, it seems unlikely. How much is the time of an engineer or technician worth? Placing vias, eyelets, and solder paste after routing is a time consuming process. Moreover, modern components with fine pitch leads require significant attention to solder. This is aside from the expense of the router and reflow oven. Is it worth solving a manufacturing problem rather than an engineering problem to shorten the time to having a board in-hand rather than spending that time developing firmware and test plans?

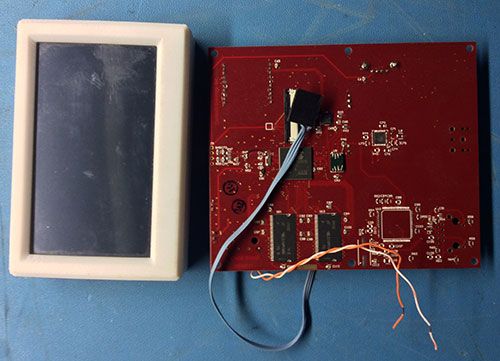

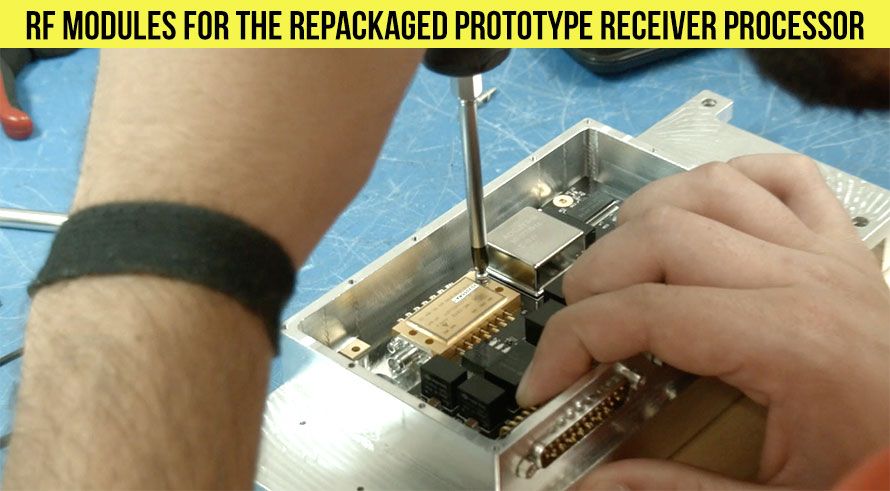

Developing a prototype shows the value and feasibility of a design idea. Taking a concept from a development board to a meaningful object may require more than showing that a processor can meet power, performance, and interface requirements. The person evaluating a project’s success or failure may not understand fully the deeply technical merits. Packaging matters more than many engineers realize. Do not let 98% of a project’s hard effort fail for a lack of 2% cleanup effort. Printing a case to house a bare board may completely alter the project’s perception.

Vendors publish schematics and documentation to recreate development kits to sell parts. This often includes mechanical models. Leverage these to meet project needs. Simple price per part and development toolchain does not completely inform an engineer to the vendor’s part in reducing development cost.

Does the vendor provide any of the items listed below? If not, other vendors may need to be selected.

- 3D models of kits and components

- Electrical models for simulation

- Example code

- Product samples

- Webinars or videos

- Documentation (not all documentation is created equal)

- Can you easliy find answers?

- How well is it organized

- For documentation distributed among several publications, is it clear what is offered in each?

- Product shortcomings

- Respect a vendor that publishe problems prominently

- Be leary of vendors that downplay serious issues

- Communication availability

- Direct (e.g. email, telephone)

- Community (e.g. forums)

Projects success requires communication and evaluation. Schedule shortcomings may require time extensions, but alteration of goals may be more acceptable in a prototype phase. The importance of a prototype is to present the design’s value, and how major technical challenges may be overcome. Successful engineers evaluate, discern, and act. Working hard shows best when done so wisely.