As a mechanical engineer, you’re a problem solver. That is a pretty broad description. A Mechanical Engineer could be designing, testing, and developing some product that solves a problem. They could be trying to identify the best way to move heat away from, or toward something. A mechanical engineer may develop a brand new device that removes some of the efforts of humans to perform a task, like Archimedes’ screw and the block-and-tackle pulley system.

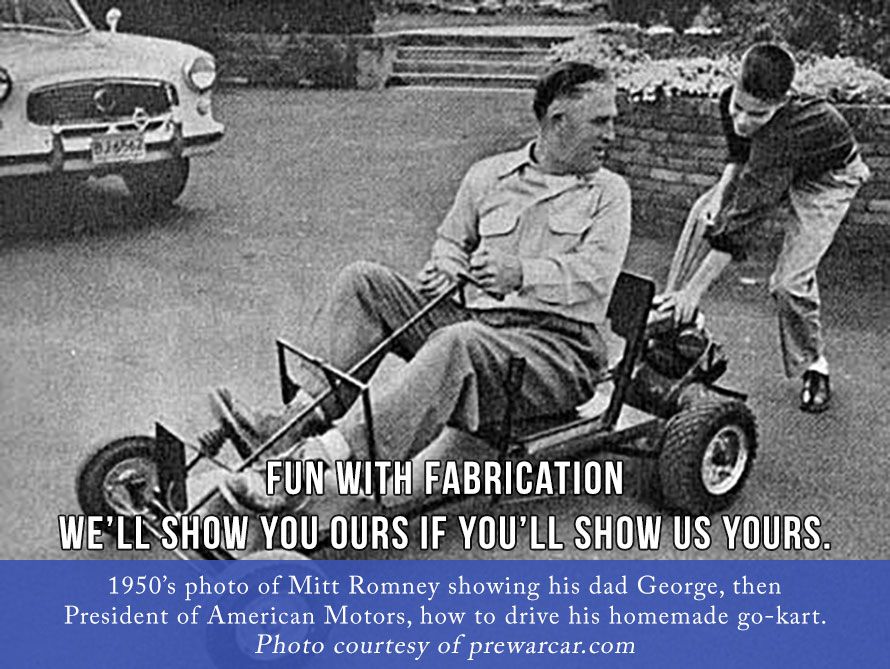

Click to also read Fun With Fabrication

The Mechanical Engineer, sometimes referred to as a Mech.Es, Gearhead, and even just ME, is one of the oldest branches of engineering. Mechanical Engineers have built coliseums, pyramids, great walls, and war machines like ships, missiles, and rifles. They need to have an understanding of thermodynamics, materials, structural analysis, electricity, kinematics, and more in order to build structurally sound buildings, bridges, mechanical devices, and even the tools and equipment that support and maintain other machines and apparatuses.

“A good scientist is a person with original ideas. A good engineer is a person who makes a design that works with as few original ideas as possible. There are no prima donnas in engineering.” ~ Freeman Dyson

Mechanical engineers have a wide range of areas of interest when it comes to jobs and work in the industry. In any given field, some areas of interest are more focused on than others, but overall mechanical engineers have to be aware of these subjects and how they impact their designs, decisions, and day-to-day problem solving approaches.

6 Areas of Interest in the Mechanical Engineering Field

- Environment

The environment is an area of interest for many different types of industries to consider. For mechanical engineers, it is the effects of their designs on the environments, as well as the effects of the environment on their designs, with which they would be concerned. At Duotech Services, when dealing with equipment that can easily be disrupted by environmental effects in aircraft, the environment is a big factor in how enclosures are designed and considered in any probable environmental situation. - Dynamics

At the heart of most moving or changing physical systems is a mechanical engineer who has tested, researched, theorized and computed every movement of that system and how to optimize it. The optimization usually consists of dynamic theories being experimented with using computational, iterative methods. One way Duotech Services uses these testing methods in their designs is when analyzing vibrational effects on equipment in an aircraft. - Energy Systems

When considering how energy is stored, used, and controlled, mechanical engineers have to consider a large spectrum of possibilities. There are many energy sources like oil, natural gases, wind, water, and many more that can all be applied in different ways. In any dynamic system, energy must be stored and used at some point and, therefore must be able to be controlled so that it can be applied at the right moment in the right quantity. When dealing with the aerospace industry, Duotech is able to provide systems for aircraft that are cooled based on the requirements provided by the customer. Thermodynamics and heat transfer are two of many topics that mechanical engineers study and are concerned about in a design including an energy system. - Manufacturing

Manufacturing is a very broad area of interest, especially as it is evolving and changing as technology is developing. A mechanical engineer may be interested with any one of a variety of these topics, including, but not limited to, automated manufacturing, quality control, precision manufacturing, development of tools, and optimizing processes. Duotech has the capability to manufacture a variety of parts right in our facility, enabling us to monitor and ensure the process of making the parts conform to quality requirements. From metal, to plastic, to rubber and more, it is important to use the right equipment and processes to ensure the final product meets and exceeds all the requirements for its use. - Material Science

Behind any part, product, or assembly is an analysis of all of the materials being used and how their specific characteristics affect the design. Materials are generally chosen based on their performance in the given application and sometimes even tailored to fit specific applications. When dealing with such a sensitive industry like aerospace, engineers at Duotech Services must consider carefully what materials will be efficient and effective for specific applications, most often looking at applications involving the cooling of electrical components in an enclosure at high altitudes in an aircraft for varying periods of time and use. - Mechanical Design

The process of how an idea becomes reality is what mechanical engineers call mechanical design. Starting at collecting requirements then creating a conceptional idea and creating the detailed design, all processes require some thought and analysis. Even looking past the initial design phase to steps like what manufacturing processes will be used, how the part will be quality assured, and even what the life-cycle of the part will be are all considerations in the mechanical design. Duotech Services has the capability to see parts from concept to reality by performing the design process in-house. This not only cuts down costs by keeping the whole process within the same company but also allows us to ensure the customer’s desires are being met with a high-quality designed and manufactured part.

Adapt and Overcome

Mechanical engineers specialize in adapting to their environments to identify the best possible solution to a problem and then utilizing all that is around them to achieve that goal. A jack-of-all-trades, the MechE is a problem-solver in the aerospace industry. It may mean they are using software and a CNC mill to construct mechanical parts for a receiver/processor case in a radar system or designing and producing a large test stand that performs automated tests in an aerospace or industrial environment.

A Team of Engineers You Can Trust

With over 34 years of experience, Duotech employs a quality team of experienced design and test engineers. Innovative solutions provide expedited time to market and open your resources for other project specifications. If your project requirements involve electronics design, Duotech provides you capabilities as an extension of your team for aerospace, maritime, industrial, and military electronics requirements.