Electrostatic discharge, or ESD, is a flow of electricity between two electrically charged objects when they make contact. If you’ve been shocked by someone after walking across a carpeted floor, you have experienced ESD. If you’ve been shocked when you touched your car door handle on a dry winter day, you have experienced electrostatic discharge.

Electrostatic discharge, or ESD, is a flow of electricity between two electrically charged objects when they make contact. If you’ve been shocked by someone after walking across a carpeted floor, you have experienced ESD. If you’ve been shocked when you touched your car door handle on a dry winter day, you have experienced electrostatic discharge.

These two types of ESD occurrences may seem to be minor, but when it occurs during contact with an electrostatic discharge-sensitive (ESDS) device, a minor shock to you will be like a lightning strike to a circuit board.

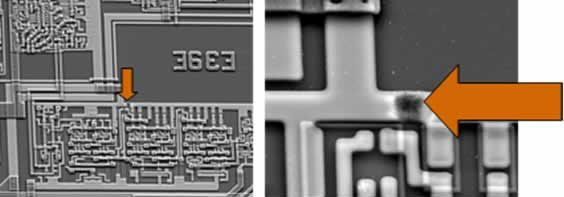

You can see the destruction a lightning strike can cause when you see a tree that has experienced it – a blackened, broken tree that is likely dead from the experience. In the picture below you can also see the destruction of ESD, a blackened break in a circuit.

When repairing customer assets, it is important to avoid causing more damage to the device than it already has. ESD damage to a circuit board in an aircraft’s avionics devices, radar systems, and communication equipment can not only mean lost revenue for the repair source but also will create delays while replacement parts are ordered, likely keeping aircraft grounded and unable to perform its mission.

When repairing customer assets, it is important to avoid causing more damage to the device than it already has. ESD damage to a circuit board in an aircraft’s avionics devices, radar systems, and communication equipment can not only mean lost revenue for the repair source but also will create delays while replacement parts are ordered, likely keeping aircraft grounded and unable to perform its mission.

In order to prevent accidental electrostatic discharge in a repair environment, a company should have an ESD Control Program. Below is a recommended list of prevention techniques.

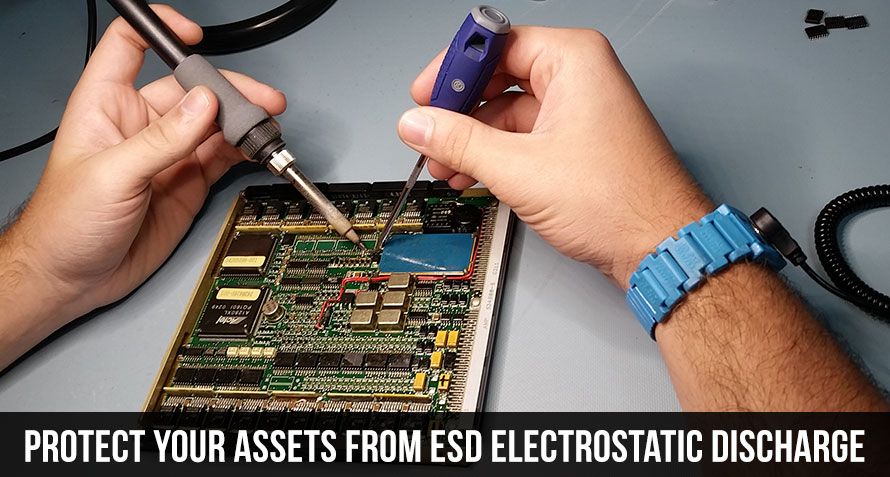

4 Ways to Protect Your Assets from ESD Electrostatic Discharge

- Proper Storage – When customer assets are awaiting repair, they should be stored appropriately. Designate and clearly label these areas. ESD items should be stored in properly labeled and closed static-shielding materials. Units that have enclosed electronics should have conductive connector caps installed.

- ESD Protective Mats – Each repair work station should have an ESD protective table mat made of static-dissipative material connected to a certified hard ground.

- Wrist Straps – A wrist or ankle strap should be worn by any technician who will be touching exposed circuit boards. Individuals should test these straps at authorized strap test stations daily. Make sure you get a good connection between strap and skin, even using a moisturizer to eliminate dry skin.

- Training – Require annual training to ensure all employees know and follow the procedures set by your ESD control program to avoid electrostatic discharge during handling of customer assets.

To avoid unnecessary repair costs and delays, your company should have an ESD control program in place. Ensure all employees are informed on what procedures to follow and hold required training sessions to refresh everyone on a regular basis. Test your protective equipment frequently to ensure they are working properly before beginning any maintenance processes.

Download Free Workplace Safety Checklist