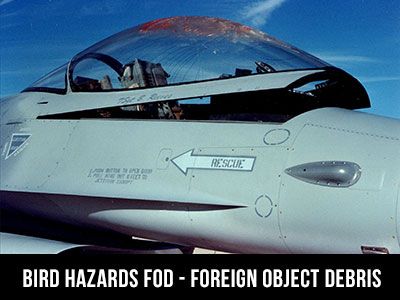

What are foreign object debris (FOD) and foreign object damage (also known as FOD)? If you are driving down a highway and pass by a large tread that has come loose from a semi truck’s tire, you’ve seen foreign object debris. If you were unfortunate enough to run over that remnant of the truck giant tire, you likely have foreign object damage.

Foreign object debris is any item, material, or substance that is in a place it is not supposed to be that can cause damage to equipment or personnel. Foreign object damage is the damage that is caused by foreign object debris.

Foreign object debris is any item, material, or substance that is in a place it is not supposed to be that can cause damage to equipment or personnel. Foreign object damage is the damage that is caused by foreign object debris.

Foreign object debris and damage can occur on a highway, like an old tire running under your car, or a rock that bounces up and cracks a windshield. At a race track, you can see safety personnel picking up FOD after a wreck. At an airport, FOD can be loose parts that have fallen off an aircraft and can be extremely dangerous to other planes around a runway. FOD can be birds around an airport that can cause dangerous situations during takeoffs and landings.

FOD in a manufacturing and repair environment can be tools that were not accounted for and left inside equipment. It can be parts and fragments, or even dirt, remaining loose inside from a repair.  Foreign object debris can contaminate, cause damage, or destroy products and equipment. It also has the potential to lower quality standards and injure personnel.

Foreign object debris can contaminate, cause damage, or destroy products and equipment. It also has the potential to lower quality standards and injure personnel.

Some examples of foreign object debris in a repair depot are tools, loose hardware, paper clips, repair materials, food, food wrappers, sand and dirt, and even the materials necessary to repair the equipment.

If your company does not already have a FOD Prevention Process, you should make it a priority to establish one. Below are examples to eliminate FOD in your business that will help you get started.

7 Ways to Eliminate FOD in a Repair Depot

- Training – Periodic training of personnel to identify FOD and proper methods for removal

- Housekeeping – Keeping all work station areas clean of anything that is not necessary to the repair of the equipment at hand.

- Designate No Food Zones – Keep food and drink away from work stations. A company should designate authorized food and drink storage areas, or prohibit these items from inside a lab area completely. Individual computer workstations should also be designated “No Beverage Zones.”

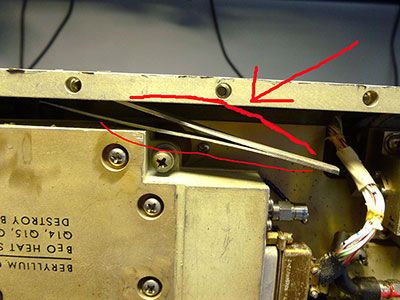

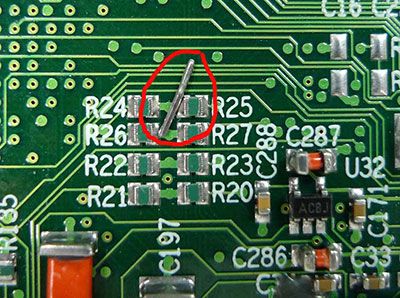

Tool Accountability – When not in use, always store tools in their proper location. During a repair, keep an account of all tools and materials at your station to avoid leaving something from the repair inside a Line Replaceable Unit (LRU) like a pair of small tweezers, or tiny fragments from a soldering repair

Tool Accountability – When not in use, always store tools in their proper location. During a repair, keep an account of all tools and materials at your station to avoid leaving something from the repair inside a Line Replaceable Unit (LRU) like a pair of small tweezers, or tiny fragments from a soldering repair- Air Filtration – A good air filtration unit for your repair station cuts down on the small particles in the air that can build up and contaminate the inside of equipment during repair

- Secure Outside Doors – Keep doors leading outside closed to avoid FOD entry into the facility. This cuts down on debris floating around in the air. This also goes for an inside area, like a paint room, that can allow FOD to enter in and land on freshly painted equipment.

- Inspect for Foreign Object Debris – Include FOD inspections as part of the repair process. This ensures that each individual in the repair process keeps an eye open for FOD and removes it accordingly.

Companies like Duotech, who provide long-term sustainment services for aircraft avionics, radar systems, weapons systems, and other mission-critical equipment, incorporate FOD inspections as part of their standard repair procedures. Eliminating FOD is critical to avoiding damaging customer-owned assets and injuries to personnel.

Duotech is AS9100D certified and is an Air Force qualified repair depot. Learn more about Duotech’s long term sustainment capabilities for your F-5, F-16, C-130, and other legacy aircraft.