What is this “Rapid Prototyping” thing that has enveloped the engineering world and beyond? Should I bring these processes into my facility? What value does it add to my organization? With the advancement to additive manufacturing, am I missing out by not joining the crowd?

If you manage a technical organization or work within one, these and other questions may have come across your mind. Rapid prototyping is an approach to bring concepts to functionally complete representations of the idea. Duotech Services, LLC. (DSI) made the move to integrate rapid prototyping processes in-house, but only those that made business sense. What matters is what makes money.

For Duotech, development of electronic devices has always been the key engineering activity, but electronic hardware always requires some mechanical design activity. A functionally complete approach to rapid prototyping provides any organization an advantage getting a solution ready for the marketplace or a customer’s evaluation most efficiently. Development of a vendor that does fabrication quickly with high reliability is a valuable resource. The time to bring a capability to your facility is when vendor solutions fall short of your needs. Below are some guidelines to consider.

Do not develop what is readily available to purchase Expand upon development kits and existing design portfolios If the processes is messy and costly, it does not belong in-house (e.g. PCB fabrication) If given the equipment, the use of it should be seamless with the use of existing design tools and workflows Do not buy equipment that will be used infrequently Do not disrupt functional workspaces for the sake of adding a capability

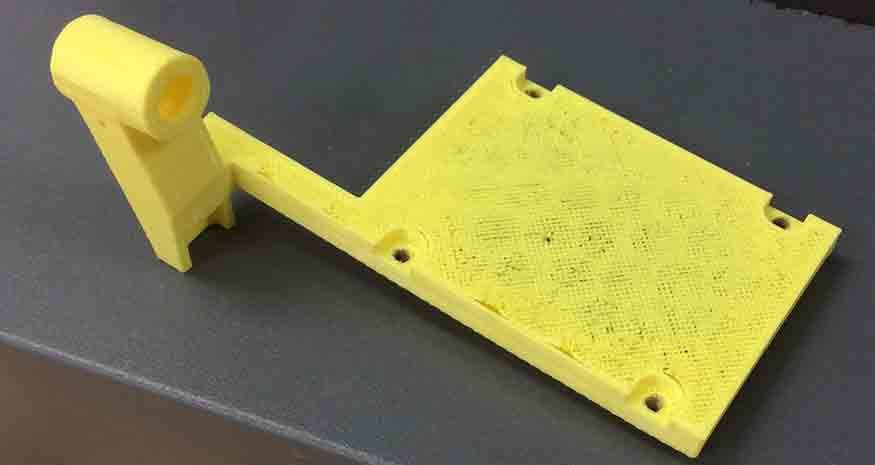

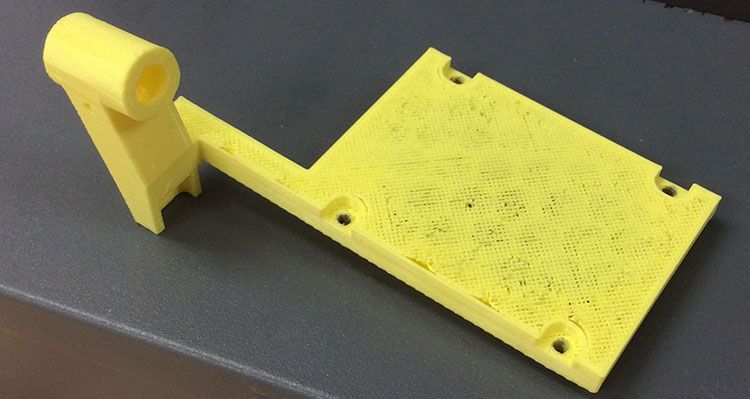

Rapid prototyping must bring a design to realization that fulfills a design intent. While printing plastics can accelerate your design cycle, consider if it provides an advantage that modern solid modeling does not fulfill. Stackups are easily determined with models, but the model may carry errors that the designer did not catch. Iteration of the design within hours rather than weeks or days pays dividends for DSI.

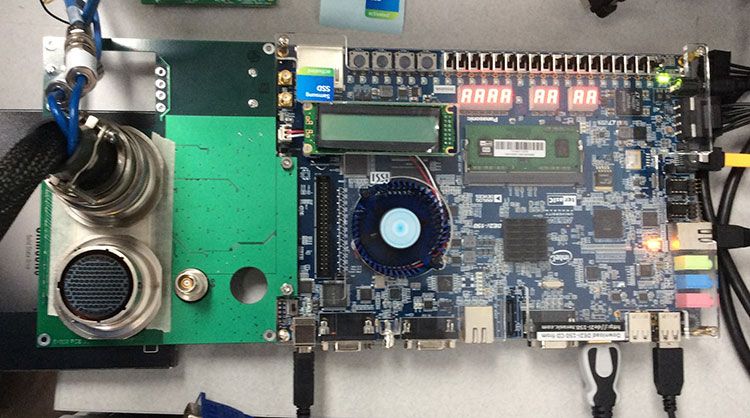

Given the choice between testing a RF design with $2,500 in COTS modules and spending three weeks working with a PCB router, which seems most advantageous? With the proliferation of connectorized modules and development kits, vendors make testing an idea easier than ever. Need a capable, inexpensive embedded computer? Any search engine will reveal dozens for less than the price of a tank of gas. Need to build a custom RF transceiver that operates in the X-band range? Filters, amplifiers, mixers, synthesizers, splitters, modulators, demodulators, couplers, power detectors, and feed lines – you can build your design in less than an hour upon delivery.

Ultimately, the NRE cost comes down to time, materials, and opportunity. Rapid prototyping lightens the load on engineering personnel and increases the flexibility to pursue opportunities. Subsequent posts in this series will detail design prototyping methodologies for electronic systems, mechanical designs, and modular design approaches.

Rapid Prototyping Part 2: Electronics